Designer & Manufacturer of Perfume Bottle Packaging

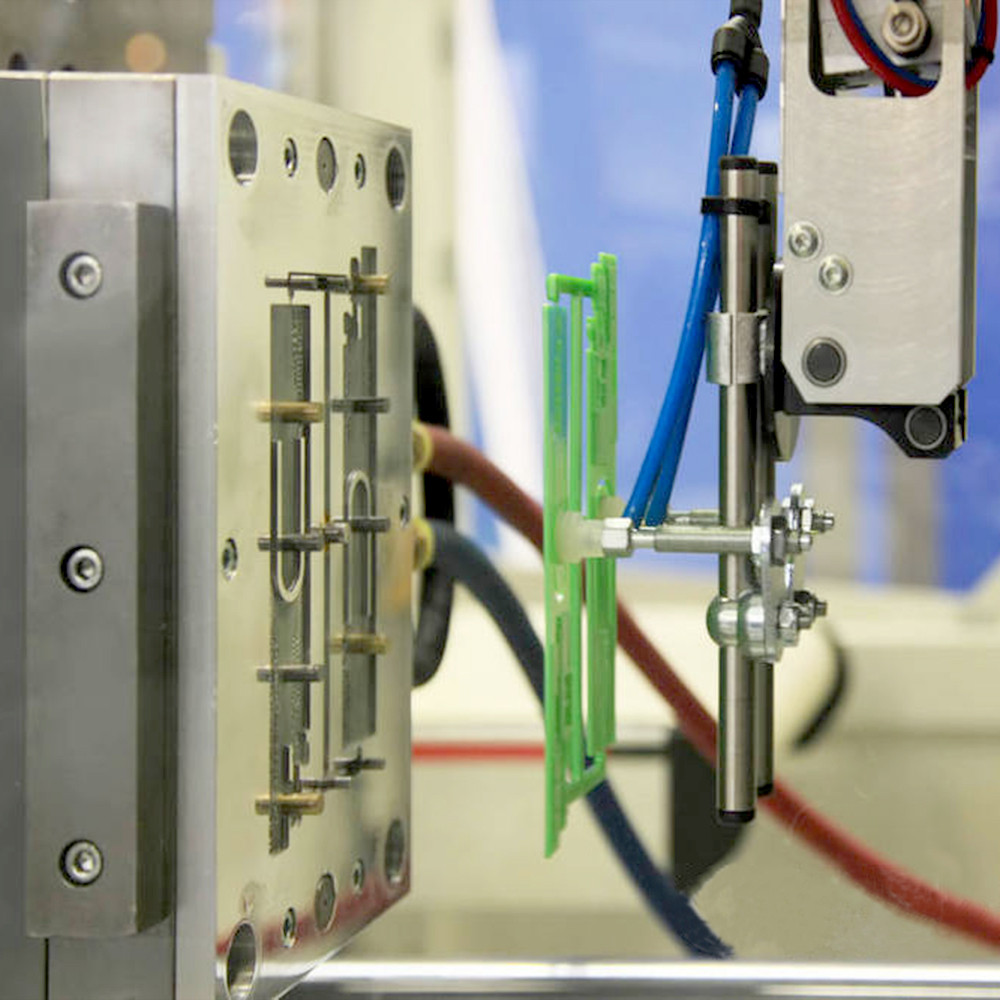

What's the mold tooling process?

GP Bottles makes high-end steel mold for glass perfume bottle, perfume cap. Before actual production, we will make a test mold to produce samples for approval, after approval, we will make the production mold. That means we can check the producion problems with the testing sample, and adjust the mold without much more cost.

Molding for glass perfume bottle

After confirming the mock-up and related drawings, we will make one glass bottle test mold to produce testing sample. We can check the weight, volume, appearance, internal modelling etc from the tesing mold. That will makes the mass production more safe, more efficient and less risk. There are total 6~8 molds to produce on the glass bottle machines in mass prodction.

Molding for perfume caps

Different from the glass bottle mold, there are 2~8 cavities core on the plastic or metal cap mold. So we will make one cavity test core to produce testing sample for approval. After approval, we will make the remaining core on the mold. We need to test the match up, weight, surface and the chemical parameters of testing sample. That's very important for the cap.

Are you looking for a reliable supplier to design and customize your perfume packaging?

We can quickly provide customers with service and solution of designing, customization and contract manufacturing.Consult GP Bottles@ Let's Create It Together

GP Bottles not only manufactures perfume bottles but also designs them to resonate with the essence and ethos of your perfume brand. Our mission is to "Elevate Scores of Your Perfume Brand" and we invite you to consult with us to collaboratively bring your vision to life.

- *Name

- *Tel

- *Title

- *Content